Watson-Marlow Fluid Technology Solutions reveals transformative Bredel CIP pump for beverage producers at drinktec

Visit stand 559 in Hall B5 to learn more about the new Bredel CIP pump

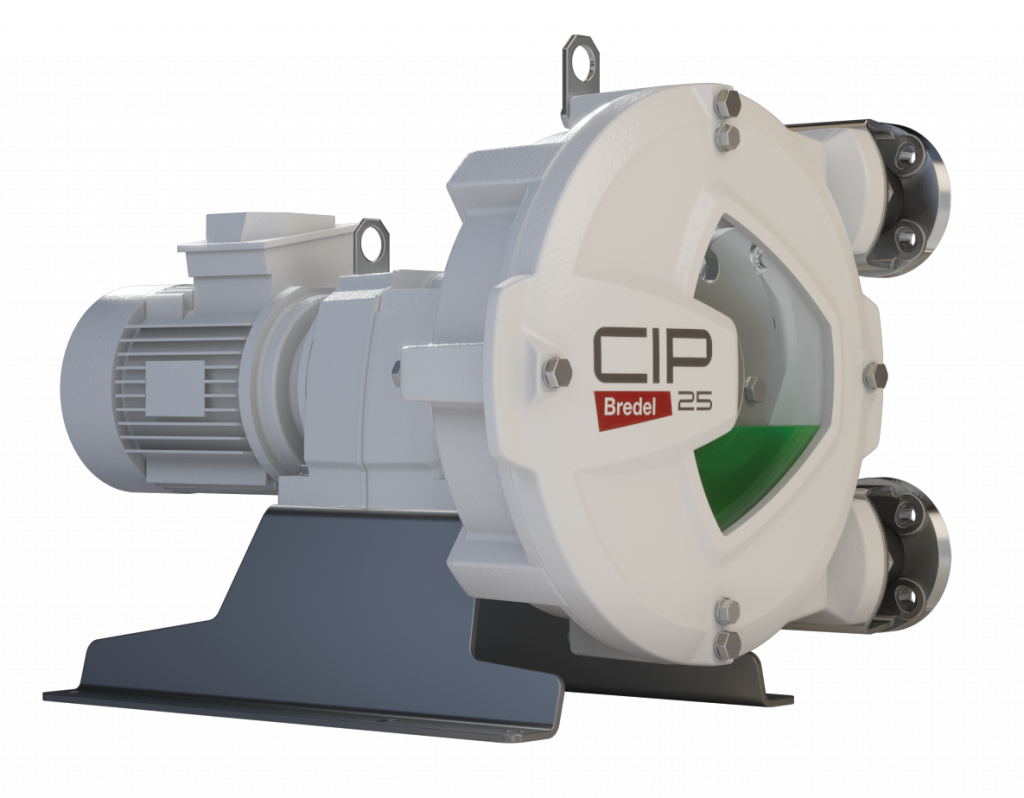

Falmouth, UK, 26th August 2025 / Watson-Marlow Fluid Technology Solutions (WMFTS) will launch the Bredel CIP pump, a transformative hose pump for breweries and beverage producers at drinktec in Munich, Germany (September 15 – 19).

At the WMFTS stand (Hall B5, Stand 559), visitors can discover the innovative Bredel CIP pump—engineered for hygienic, simplified and energy-efficient Clean-In-Place (CIP). Alongside the new pump, WMFTS will showcase a comprehensive range of peristaltic and sinusoidal pumps, as well as hoses, which enable brewers and beverage producers to boost productivity while reducing energy consumption, water usage, and waste.

The Bredel CIP is designed with a new rotor to enable companies to achieve the required CIP velocities in various applications at beverage producers. The Bredel CIP pump features automatic retractable compressing shoes that fully open the hose, allowing CIP fluid to flow at the optimal velocity for effective cleaning. By retracting the shoes during cleaning, hose compressions at high temperatures are eliminated, thereby extending hose life and reducing costs of replacement hoses.

For beverage and liquid food producers, Bredel CIP is ideal for transferring fruit puree, fruit concentrate, liquid sugar unloading, and flavour and colour dosing. Bredel hose pumps are widely used in beverage production due to their ability to reliably handle shear sensitive, abrasive or viscous products.

Steffen Knoedler, Global Business Development Manager – Food & Beverage at WMFTS, said: “The Bredel CIP sets a new benchmark in peristaltic hose pump technology for breweries and beverage producers. It ensures thorough CIP, eliminating the risk of spoiled product while delivering the required fluid velocity with extended hose life.

“Unlike standard hose pumps, the new pump avoids hose compression during CIP cycles by retracting the shoes while the pump remains stationary. This innovation significantly reduces wear during high-temperature cleaning, extending hose life and lowering replacement costs.

“The Bredel CIP also reduces energy consumption, as there’s no need to operate the pump during CIP. This combination of efficiency, reliability, and cost savings makes it a game-changer for hygienic fluid handling in beverage production.”

Peristaltic and sinusoidal pumps from WMFTS transfer viscous products such as fruit concentrate and overcome the most demanding of suction conditions to minimise process time without affecting product integrity. Certa Sine pumps from MasoSine and Bredel hose pumps are specifically designed to handle the high viscosity, temperature and pressure challenges faced by beverage producers. Certa pumps have been integrated into beverage systems for blending syrup of different viscosities and other beverage ingredients while Bredel is used for transferring viscous fruit concentrate by a drinks manufacturer.

Products on display at drinktec include:

- Bredel CIP. The new pump, specifically designed for CIP processes, is available in sizes 20 (600 L/h), 25 (1800 L/h) and 32 (3200 L/h). Existing customers can easily upgrade their pump rotor to the CIP variant in-situ without removing the pump from the process line.

- Certa Sine® pumps from MasoSine are very easy to clean and perfect for handling viscous fluids. Due to its one shaft, one seal design, Certa is considerably more energy efficient than other positive displacement pumps. Certa pumps are widely used by food and beverage companies for their gentle handling and easy CIP.

- The Qdos® range of chemical metering and dosing pumps offers reliable and cost-effective performance for water and wastewater treatment in a wide range of brewery and beverage processing plants and applications. Qdos H-FLO, the latest addition to the range, is designed specifically for higher flow rates up to 600 L/hr. Qdos and Bredel hose pumps are designed to work without high-cost ancillaries like back pressure valves, seal-water flush systems, or run-dry protection.

- Watson-Marlow 530 cased pump delivers accuracy of up to +/-0.5% to guarantee process stability and product quality. A closed fluid path pumping ensures complete isolation from any source of contamination during transfer and filling applications.

- Lined with polytetrafluorethylene (PTFE), Aflex hoses offer excellent chemical resistance and are ideal for the beverage industry. Aflex FaBLINE hose is a food-grade flexible hose developed to meet the latest hygiene standards.

Visit WMFTS at stand 559, Hall B5 at the Trade Fair Center Messe München to explore how its advanced pump and hose technologies can support sustainable, efficient, and hygienic production in the beverage production sector.

ENDS

For further information, please contact:

Sciad Communications, Media Relations

Juliette Craggs

E: WatsonMarlow@sciad.com

T: +44 (0) 20 3405 7892

Notes for Editors

About Watson-Marlow Fluid Technology Solutions

Watson-Marlow Fluid Technology Solutions (WMFTS) is a world leader in manufacturing peristaltic pumps and associated fluid path technologies for the life sciences and process industries.

As a leading provider of peristaltic and sine pumps, automated filling machines, tubing, hoses, fluid path components and post-sales support technology, WMFTS partners with customers to solve challenges across various applications.

WMFTS is a wholly owned subsidiary of Spirax Group, with operating units worldwide.

Further information can be found at www.wmfts.com

Watson-Marlow

Watson-Marlow Fluid Technology Solutions (WMFTS) is the world leader in niche peristaltic pumps and associated fluid path technologies for the food, pharmaceutical, chemical and environmental industries. Comprising ten established brands, each with their area of expertise, but together offering our customers unrivalled solutions for their pumping and fluid transfer applications.

Got an innovation you need bringing to life?

We’d love to hear from you! Head to our contact page to start a conversation.